The pandemic has left lasting impressions on the workplace. As businesses adapted, roles and responsibilities changed. Some businesses were forced to lay-off staff or rely on temporary staff to meet new and fluctuating demands.

New processes were also introduced, whether to deal with the restrictions that were in place or to accommodate a shift in the business’s operations, for example the addition of meal delivery to a restaurant.

Unfortunately, with many businesses focusing on survival and meeting all the requirements to reduce the transmission of Covid-19, routine health and safety was often put on hold.

Now, although normality has returned, many businesses are still trying to catch up with their health and safety training or refresh what they provide to reflect changes in the business.

“The pandemic led to a reliance on digital training. Whilst we embrace the use of on-line training methods for some topics, we’ve seen examples from the HSE where this has been less effective than on-site, face-to-face training, ultimately contributing towards workplace accidents,” states Mark Merrix, head of casualty claims at Allianz.

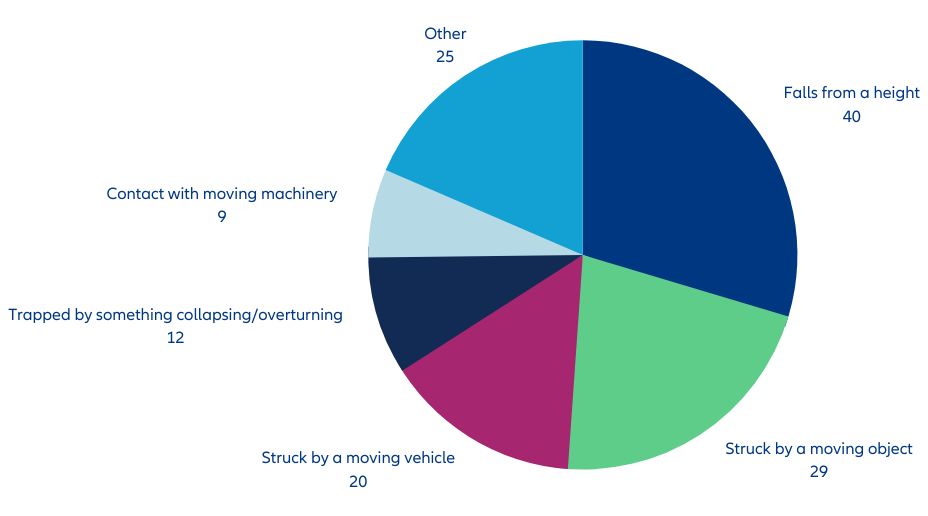

“For training to be effective, it is essential that companies select the right topics for digital courses or use a combination of online and face-to-face onsite training. This is especially important for new starters who don’t know the business or the environment they’re stepping into, in particular when it comes to those high risks of machinery operation, vehicle movements and working at height,” explains Mark Pearce, loss control technical lead at Allianz.

Helen Bancroft, casualty account manager at Allianz, adds "It’s how we approach training here at Allianz. We see real value in face-to-face training and mentoring, combined with digital courses."